Our Journey from Pioneer to Leading Provider

1969: Our Story Begins

1969: Our Story Begins

Vibrational stress relief began before 1950 when the United States Navy and the German defense used harmonic vibrations (also called resonant vibrations) to test metallic boat hulls and airplane wings. Usually, vibrating metal components at resonant frequencies causes the metal to undergo large amplitude deflections and, if sustained for long periods, causes the component to fail. Researchers found, however, that if this vibration test did not break the components, they would not fail in service. It was recognized that vibrating the metal at its resonant frequency would sometimes remove heat stresses, and sometimes it would not. In time, resonant vibrations were used haphazardly to attempt to relieve heat stresses, but the results were unpredictable and inconsistent.

As a precision planer-mill machine facility, Bonal Corporation became interested in this process in 1969 as a way to provide high quality, in shop, heat stress relief without the large ovens needed for heat treating. The corporation bought a vibratory stress relief system to put to immediate use in their machine shop.

A New Discovery

A New Discovery

However, after recognizing the inadequacy and inconsistency of resonant vibrations to produce consistent heat stress relief, Bonal engineers studied the process and discovered that the secret to successful vibration stress relief lay in two areas:

- Vibrating the metal in the Sub-Harmonic zone; and

- Monitoring the harmonic frequency. If a component has heat stress in it. the frequency of the harmonic curve will first shift and then stabilize at its natural location.

This improved Sub-Harmonic process achieves both consistent and predictable stress relief.

Bonal Corp. Patents the Meta-Lax® Process and Technology

Bonal Corp. Patents the Meta-Lax® Process and Technology

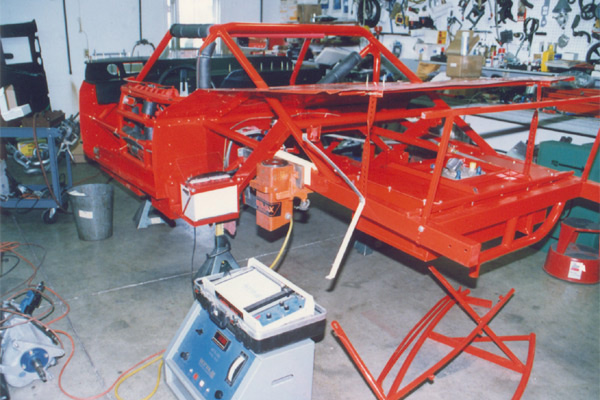

Bonal Corporation engineers contacted the vibrational stress relief company about improving the stress relief process. After their suggestions were explicitly turned down, Bonal patented this improved process and initiated further pioneering research into the new “Meta-Lax” (metal relaxation) technology. The result is Bonal Technologies, dedicated to continually improving and leading this state-of-the-art technology into the metalworking marketplace.

The Meta-Lax process removes thermally induced residual stress caused by rapid heat reduction by applying mild vibrations to a metal component at a Sub-Harmonic frequency, producing accelerated motion of the atoms in the crystal. With the addition of vibrational energy, the atoms maximize their coulombic (electrostatic) attraction and restore the natural crystalline configuration.

Bonal’s Meta-Lax process speeds this natural transformation so that it occurs in 20-40 minutes for most metals, with obvious benefits to the metal.

Bonal International, Inc. is Formed - 1984

Bonal International, Inc. is Formed - 1984

Soon after, Meta-Lax technology brought about a new breakthrough for the fabrication industry. Through a specialized process called Meta-Lax Weld Conditioning, welders were able to do something they could never do before: weld a part while inducing negligible stress. It was also found that Meta-Lax Weld Conditioning yielded several other benefits to welders and their products.

To manufacture and market Meta-Lax, a separate company, Bonal Technologies, Inc. was formed. Later it became a public company as a subsidiary of Bonal International.

Bonal and Meta-Lax® Today

Bonal and Meta-Lax® Today

Today Meta-Lax equipment is sold throughout the US and in 64 foreign countries through a network of national and international distributorships.