Meta-Lax®: An Innovative Solution to the Manufacturing Challenges of the 21st Century

The manufacturing challenges of today and tomorrow cannot be mastered with yesterday’s process and equipment. More products are being created for smaller niche markets around the world, requiring manufacturers and their suppliers to contend with:

- Smaller Volume Product Runs

- Shorter Lead Times

- Reduced Tooling Times

- Higher Quality Tolerances

- More Competitive Pricing

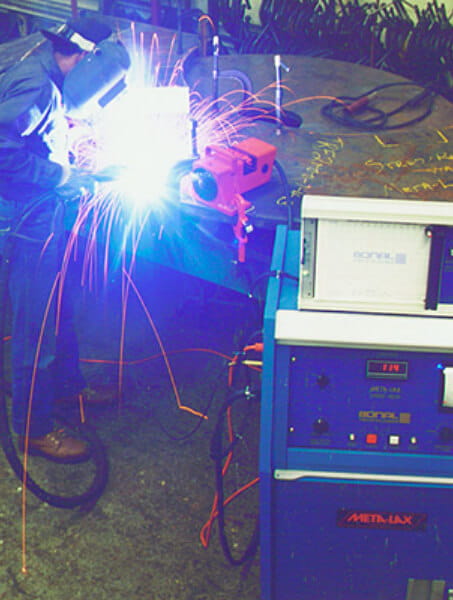

If your company is into welding, machining, grinding, mold making, die casting, EDM, or heat treating, and you want to reduce the time and cost of stress relief or improve quality, you need to bring stress relief in house and with a process that is reliable, measurable, fast and cost-effective. The only stress relief process and technology that meets all those conditions is Bonal's Meta-Lax® stress relief process.